- +44 (0)1953 454540 enquiries@stuartwells.co.uk

Loading ...

Client: NNB BYLOR JV

Location: EDF Hinkley Point C, Somerset

Duration: 2017 - 2020

Project Overview

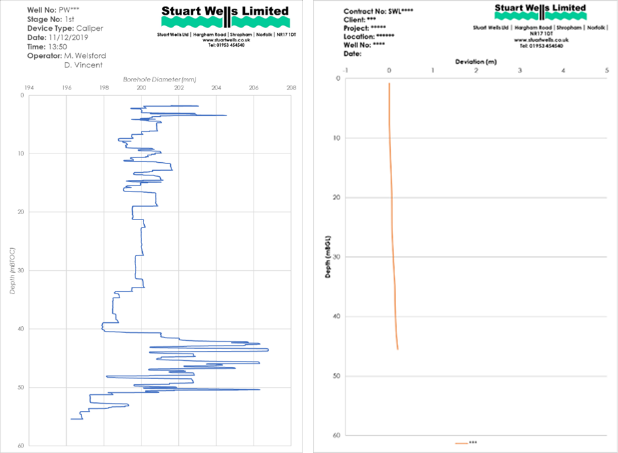

As part of the permanent groundwater control design to reduce porewater pressure, a series of passive pressure relief wells. Phased works involved the drilling of permanent pressure relief wells upto 70m deep using rotary drilling methods terminating in 200mmØ with an internal installation of stainless steel 90mmØ well liner. In-line with Nuclear New Build quality controls, extensive geophysical logging, analysis and interpretation was undertaken on all of these pressure relief wells and comprised of using the following tools.

To comply with specification requirements, verticality sondes were utilised to log inclination during and after the drilling process of the pressure relief wells. Our verticality testing is installed with a gyro device which prevents it being affected by steel sections and magnetic anomalies downhole.

Borehole Diameter Calliper TestingCalliper testing was undertaken to highlight any major fractures and fissures in the bedrock and to enable adjustment to well design if necessary. A 3-Arm tool with 600mm max range and +-3mm accuracy was utilised for the works.

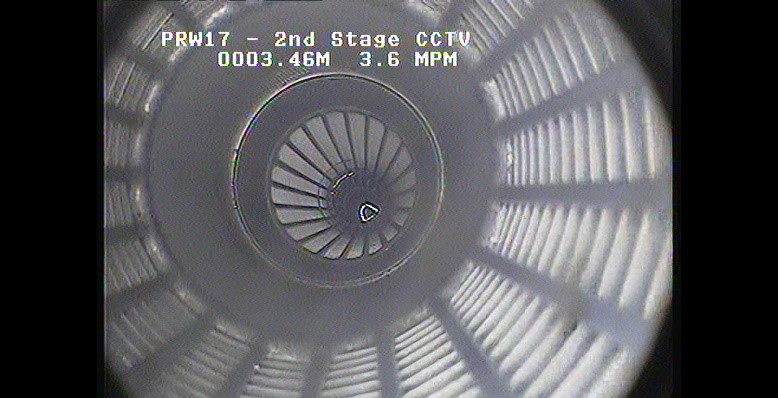

Borehole CCTVFull CCTV surveys were undertaken open hole after completion of drilling, and after the steel well liner had been installed to ensure that there were no fundamental issues with the integrity of the well. To log these, an axial colour camera was used for CCTV investigations, recording every aspect of each well.

Quality & ReportingFor comply with the extensive quality specification, records and quick geophysical analysis was required with interpretation and analysis of logging results. Thorough and highly detailed logs were produced and records kept with detailed information regarding the parameters of all conditions found.

Copyright © 2025 Stuart Wells Limited, all rights reserved.