Epworth STW

- Client: NMC Nomenca

- Location: Epworth STW, Lincolnshire

- Duration: September 2014 - December 2014

Wellpoint dewatering with settlement and groundwater level monitoring and assessment

Objective

Stuart Wells was contacted by the client amid concerns of subsidence due to groundwater level reduction beneath existing structures. The design criteria was to reduce the groundwater level to enable the construction of four final settlement tanks with settlement and groundwater level monitoring.

Project Overview

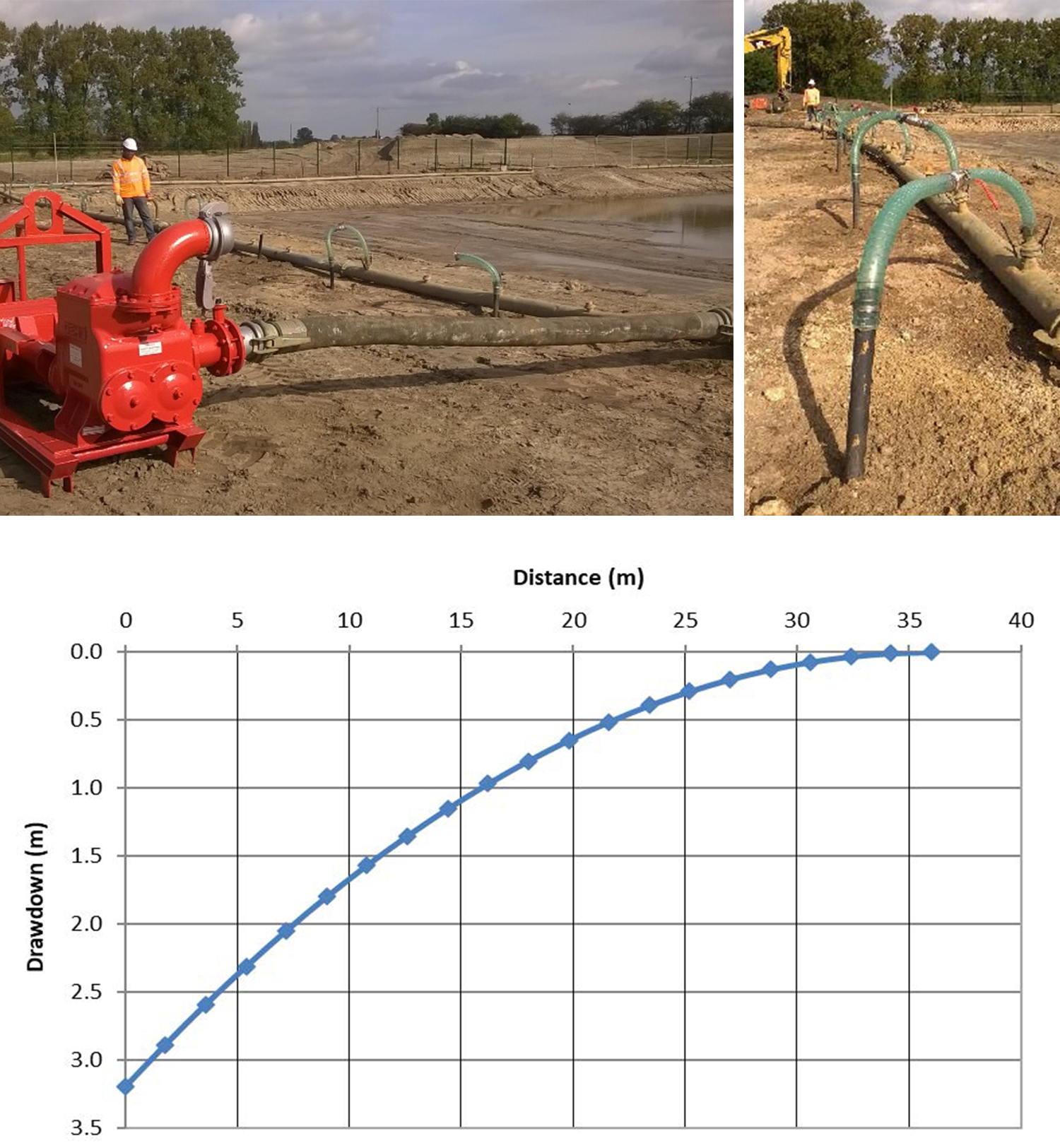

Dewatering required for 2no Oxidation and 2no FST Tanks within a single 65m x 45m open-cut excavation upto 4.7m deep below ground level. Settlement concerns were raised over groundwater level reduction beneath existing structures within the works. An estimated distance/drawdown profile was established based on design bulk permeability of k = 5.6 x 10-5 m/sec. In turn this was used together with a range of soil one-dimensional compression vales to undertake a settlement risk assessment due to increases in effective stress. In addition a filter pack design assessment was undertaken to mitigate any risk of settlement due to loss of fines.

Project Detail

| Ground Conditions: | Top soil | 0.0m to 0.35m BEG |

| Silty Sand | 0.35m to 4.7m BEGL | |

| Firm Clay | 4.7m to 8.2m BEGL | |

| Groundwater Level: | 1.3m BEGL |

Scope of Works

Temporary Vacuum wellpoint system installed at nominal 2.0m centres around the perimeter of the works to top of Clay using conventional water jetting installation method. Provision for 6no access points into the works area. Once bulk dewatering achieved, dewatering changed to conventional sump pumping within perimeter slip trench at toe of batter.

The wellpoint dewatering system divided into two parts each pumped by a 150mm Ø 415V piston pump connected to works mains power. Discharge via v-notch settlement tank with calibrated flowmeter into the STW works.

Both settlement and groundwater level monitoring was carried out across the site.

Downloadable PDF

Wellpoint Dewatering - Epworth Sewage Treatment Works

Related Case Studies

- Ashby Folville Manor

- Basement Extension

- Hook WwTW

- Islington Pump Station

- Llanberis WwTW

- Mersey Gateway

- Paull TBM Shaft

- Unity Square

- Saint Gabain Glass Factory

- Laing O’Rourke

- Great Wakering

- Northern Gateway

- Savill Court

- EDF Hinkley Point C

- UCLH Proton Unit

- Werrington

- Kensington

- Kenilworth

- UCLH

- HS2 River Leam

- Toddbrook Dam

- HS2 River Avon

- Ardesier Port